Collection: Diemaking Services - Molded or Engraved Rubber

Put our 60+ years of experience in molding and laser engraving rubber to work for you!

Send your artwork to us "camera ready," meaning that it is in black ink on clean, unlined white paper or poster board. You can also e-mail the artwork to us. Since your costs are determined by the total number of square inches submitted, place your designs close together. You only need to leave enough room between designs to cut them apart. Determine the total to the nearest image size; for example, an image area measuring 7 1/4" x 9 1/2" = 68 7/8 square inches and will be considered as a 70 square inch area.

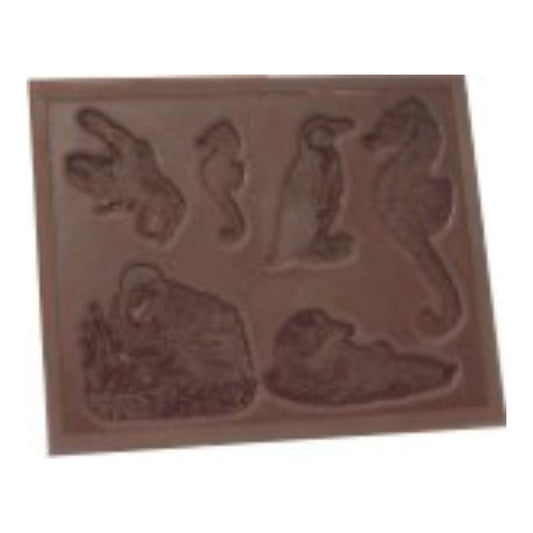

Rubber Dies are initially a three-step process:

1) The MAGNESIUM MASTER PLATE is a one-time item used to form the matrix mold. Two thicknesses are offered. "Standard Etch" will create stamp printing characters that are about .040" high, suitable for most "business stamp" type of applications. "Deep Etch" will create stamp printing characters that are about .070" high which is most common for "art stamp" applications, stamping on cloth, corrugated cardboard and other irregular surfaces.

2) The MATRIX MOLD is also a one-time expense. It is placed in the vulcanizer with the rubber to form the actual stamp printing dies. Two thicknesses are offered to correspond to the Magnesium Master Plates listed above.

3) RUBBER DIES are the printing portion of the stamp. Once formed from the Matrix Mold, they are cut apart and mounted on your choice of stamp mount. Cost for molded rubber is very low (after magnesium and matrix mold are prepared). Three price categories apply as determined by the depth of the image.

Laser Engraved Rubber Dies are a one-step process.

No need to order "set-ups" like the master plate and matrix needed for molded rubber dies.

-

Laser Engraved Rubber Die Service

Regular price From $22.66Regular priceUnit price / per -

Magnesium Engraving Service

Regular price From $36.71Regular priceUnit price / per -

Matrix Molding Service

Regular price From $8.70Regular priceUnit price / per -

Rubber Die Molding Service

Regular price From $3.50Regular priceUnit price / per